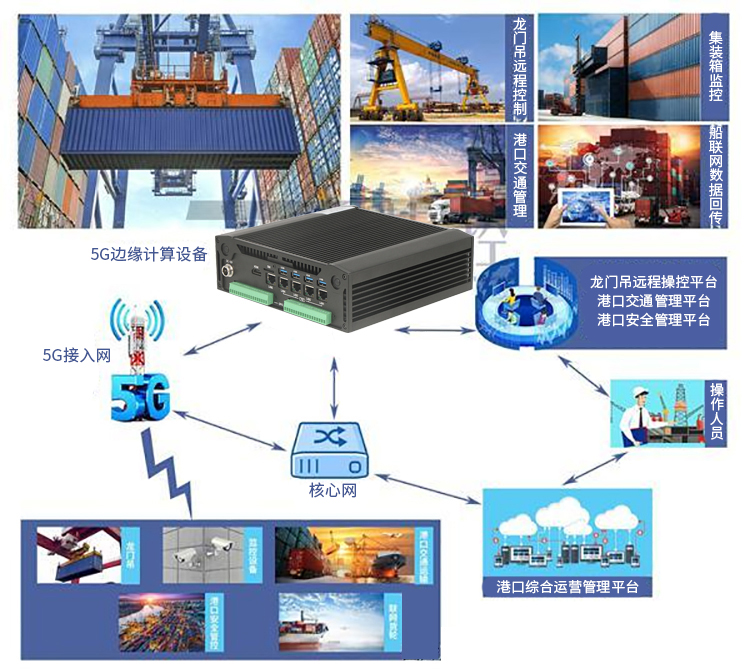

Wisdom port services include the high-definition remote monitoring, analysis of ships is artificial intelligence, high precision positioning and intelligent made driving application upgrade and innovation, intelligent power port operations, logistics service electrical business, enterprise management platform, improve port operation efficiency, promote the construction of "green, low carbon, wisdom" port type.

A typical port can be divided into six main business scenarios, respectively for ships (cargo container shipped to the port) roads, gantry cranes, loading and unloading of goods (completion of container loading and unloading of goods and handling to horizontal transportation area), horizontal transportation (land bridge to the yard area handling), yard management optimization (complete container stack), card access port (complete container in and out of Hong Kong transport) and land port transport (linkage of port and other transportation system)

Ships from shuangliu scenario involves offshore communication, synchronization, and cargo ship positioning, etc.; Gantry cranes hoisting of discharge current is optical fiber cable network and artificial operation, through the 5 g can be implemented across the bridge lifting device of remote control, which contains involves lifting equipment data acquisition, high definition video back, positioning collision, field personnel communication and identification of artificial intelligence analysis segmentation of the scene; Scenario involved within the port area of horizontal transportation vehicle automated driving scheduling, big video back, positioning collision, etc.; No stacking yard management optimization is responsible for the yard area container, need to remote control equipment, but also involve the application of AI in the visual and high clearly the video transmission; Set card in and out of Hong Kong is responsible for set card vehicles unmanned monitoring scheduling, positioning anti-collision, video transmission, etc.

The solution

5 g network performance can satisfy the requirement of the PLC control signal low latency and bandwidth requirements of the rebound, high-definition video, through the remote control of the 5 g wireless networks to replace traditional wired control, realize the scene of the homework unmanned operation, improve the operating flexibility and reliability, at a much lower labor costs, improve the working environment of workers, port operations efficiency improved significantly.

Onshore bridge and yard area, through 5 g solution, compared with the artificial pier, the single equipment can save 75% of the human, is expected to future human will be greatly reduced, the entire port at the same time, the overall efficiency increases by about 50%. In a horizontal transportation district, the application of 5 g + MEC shorten the response time of the automatic vehicle below 50 ms, transport efficiency more than 30%, and sufficient to ensure the safety of one car. Cm-level positioning precision will drive the ship the innovative application of scenarios, such as roads, will greatly improve the quality of port business of all kinds of scenario.

Through the industrial computer as calculating carrier terminal 5 g, can effectively guarantee the information feedback collection and processing.