-

副标题Gate Control Solution

副标题Gate Control SolutionBackground

The passing speed of container terminal gate is directly related to the container handling efficiency and the overall operational efficiency of the terminal. The gate is also an intersection point for the terminal and the outside (such as customs, container station and freight forwarder) to hand over equipment and exchange information. Nowadays, as terminals are committed to adopting various advanced technologies to improve the through capacity of the gate, the gate is noted for its concentration of high technologies, and serves as a window to reflect the technology level of the terminal. The gate through capability largely depends on the speed of obtaining the container number and vehicle plate number. Usually, before the containers pass the gate, the container information (such as container number, shape, dimensions, destination, discharging port, and etc.) has arrived at the TOS system by different channels. Once the container number is identified, other information will automatically be accessed, and a location will be assigned to the container. The gate also needs to identify the vehicle plate number, because sometimes the container is too small for the driver to identify, and he usually first refers to the vehicle plate number for loading/unloading. Therefore, when the container enters the gate, it is necessary to bind the vehicle plate number and the container number.Requirements for the Solution

● Embedded fanless in-vehicle computers.

● Industrial camera.

● RFID reader.

● Wide-voltage waterproof power supply.Solution

The acquisition method for container numbers and trailer plate numbers is the key to the through capability of gate. At present, technologies for acquisition of container numbers and plate numbers include Optical Character Recognition (OCR), IC card, and Radio Frequency Identification (RFID). With these technologies used and their precision improved, the terminals are developing toward unmanned gates.

■ OCR is mainly used for container number identification. The terminals only need to put OCR equipment at the gates, and do not need to coordinate trucks and other external factors.

■ The card reading success rate of contact IC card is close to 100%. However, the terminals not only need to put IC card reader devices at the gates, but also have recourse to local vehicle management authority to ensure that each truck gets an IC card and has its information read at a specified location.

■ Non-contact RFID is an upgrade product of IC card. Drivers do not need to stop their vehicles and swipe the card. RFID is a mature technology.Solution Advantages

● Fanless embedded design, small form factor, easy to be installed in a narrow space.

● Multiple I/O ports: up to 8 serial ports, multiple video input connectors, 2-9 Gigabit LAN ports and multiple DIO ports, and etc.

● Reliable product quality to meet the requirement for 7*24 non-stop operation.Application Area

● Container terminal.Warehousing -

Gantry Crane/Reach Stacker Solution

Gantry Crane/Reach Stacker SolutionBackground

For different applications such as quay cranes, yard cranes, reach stackers and forklift trucks, LYKONDA Technology has designed large-sized in-vehicle computers, and provided various mounting brackets to fasten the computers onto the cabs of different crane sizes. LYKONDA also provides various antenna options (rod, ceiling-mount or FRP), wide-voltage water-proof power supply and waterproof plug-in keyboard. All these have effectively met the customer’s requirement for stability and convenience of use.

Requirements for the Solution

● Medium/Large-size all-in-one in-vehicle computer with touchable display.

● High-gain in-vehicle wireless antenna.

● Mounting bracket.

● Wide-voltage water-proof power supply.

SolutionLYKONDA in-vehicle computers (VT family) provide 7-inch to 12.1-inch touch screens, and runs on Windows operating systems. They contain built-in WiFi, 4G LTE communication modules and GPS positioning module, to facilitate friendly human-machine operation of TOS system, and real-time transmission of dispatch orders.

Solution Advantages

● Reliable product quality to meet the requirement for 7*24 non-stop operation.

● Vehicle standard wide-voltage power input, to support various terminal truck models.

● Multiple screen size (7-12.1-inch) to choose from.

● Full Al-alloy enclosure, fanless design, to meet anti-dust, water-proof and anti-salt-fog standards for the terminal environment.

● Multiple mounting methods, which support various terminal truck models, and render reasonable and effective use of space.Warehousing -

Background Introduction

Background IntroductionFor the management of container trucks at terminals, LYKONDA Technology has designed in-vehicle computers (VT family) and in-vehicle LED displays (VLD family) on various platforms based on the terminal TOS system. LYKONDA also provides various mounting brackets to fix the in-vehicle computers in the narrow cab, and a variety of antenna options (rod, ceiling-mount or FRP), wide-voltage waterproof power supply and waterproof external keyboard. All these have effectively met the customer’s requirements for stability and convenience of use.

Requirements for the Solution

● Medium/Small-size all-in-one in-vehicle computer with touchable display.

● In-vehicle LED display.

● Mounting bracket.

● Wide-voltage water-proof power supply.Solution

LYKONDA Vehicle Mount Computer (VT family) provide 7-inch to 10.4-inch touch screens, and runs on Windows/Android operating systems. They contain built-in WiFi, 4G LTE communication modules and GPS positioning module, to facilitate friendly human-machine operation of TOS system, and real-time transmission of dispatch orders.

The in-vehicle LED displays (VLD family) are mounted in front of the windshield of the container trailer cab. VLDs receive information from in-vehicle computers by serial ports, and display it to the working staff outside the trailer, informing them the type of container lock, destination of the trailer, and etc. In this way, the working efficiency of the terminal can be improved. Furthermore, the LYKONDA TMT family products integrate the LED display and in-vehicle computer, with the LED screen facing outside, and a screen and function keys facing the driver. This all-in-one design makes it easier for customers to install and disassemble the product.Solution Advantages

● Reliable product quality to meet the requirement for 7*24 non-stop operation.

● Vehicle standard wide-voltage power input, to support various terminal truck models.

● Multiple screen size (7-10.4-inch), optional Windows and Android platforms.

● Full Al-alloy enclosure, fanless design, to meet anti-dust, water-proof and anti-salt-fog standards for the terminal environment.

● Multiple mounting methods, which support various terminal truck models, and render reasonable and effective use of space.Application Area

● Container terminal yard.Warehousing -

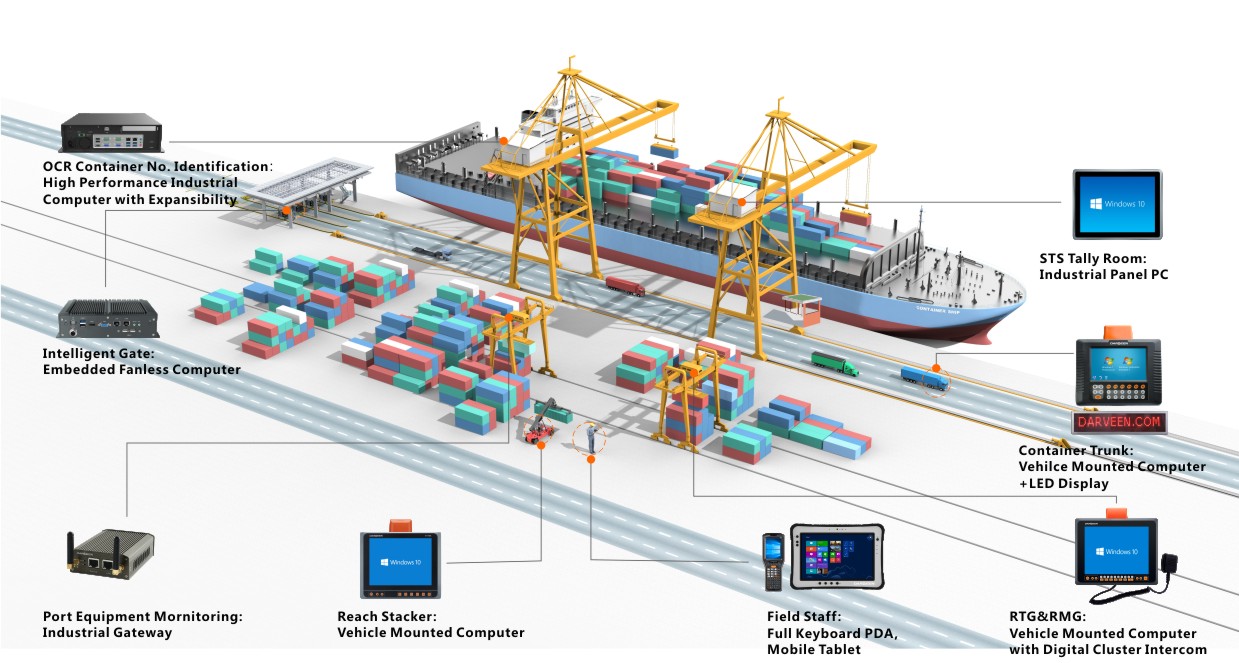

Intelligent Container Port

Intelligent Container PortIn order to meet the different needs of various industries’ fleets for vehicle mount computers, Darveen R&D team hasdeveloped many distinctive features for various applications, including more precise positioning solutions,support for CAN/OBD communication ports to acquire operating status of the vehicles, wide voltage power supply which is adaptable todifferent environments, and more wireless communication methods. After years of development, Darveen has developed aseries of products deeply adored by the users around the world.

Application Area

● Container Truck Solution

● Gantry Crane/Reach Stacker Solution

● Digital Trunking & Data Comm.

● Gate Control Solution

● OCR SolutionWarehousing

- 共1页 4条