-

副标题Gate Control Solution

副标题Gate Control SolutionBackground

The passing speed of container terminal gate is directly related to the container handling efficiency and the overall operational efficiency of the terminal. The gate is also an intersection point for the terminal and the outside (such as customs, container station and freight forwarder) to hand over equipment and exchange information. Nowadays, as terminals are committed to adopting various advanced technologies to improve the through capacity of the gate, the gate is noted for its concentration of high technologies, and serves as a window to reflect the technology level of the terminal. The gate through capability largely depends on the speed of obtaining the container number and vehicle plate number. Usually, before the containers pass the gate, the container information (such as container number, shape, dimensions, destination, discharging port, and etc.) has arrived at the TOS system by different channels. Once the container number is identified, other information will automatically be accessed, and a location will be assigned to the container. The gate also needs to identify the vehicle plate number, because sometimes the container is too small for the driver to identify, and he usually first refers to the vehicle plate number for loading/unloading. Therefore, when the container enters the gate, it is necessary to bind the vehicle plate number and the container number.Requirements for the Solution

● Embedded fanless in-vehicle computers.

● Industrial camera.

● RFID reader.

● Wide-voltage waterproof power supply.Solution

The acquisition method for container numbers and trailer plate numbers is the key to the through capability of gate. At present, technologies for acquisition of container numbers and plate numbers include Optical Character Recognition (OCR), IC card, and Radio Frequency Identification (RFID). With these technologies used and their precision improved, the terminals are developing toward unmanned gates.

■ OCR is mainly used for container number identification. The terminals only need to put OCR equipment at the gates, and do not need to coordinate trucks and other external factors.

■ The card reading success rate of contact IC card is close to 100%. However, the terminals not only need to put IC card reader devices at the gates, but also have recourse to local vehicle management authority to ensure that each truck gets an IC card and has its information read at a specified location.

■ Non-contact RFID is an upgrade product of IC card. Drivers do not need to stop their vehicles and swipe the card. RFID is a mature technology.Solution Advantages

● Fanless embedded design, small form factor, easy to be installed in a narrow space.

● Multiple I/O ports: up to 8 serial ports, multiple video input connectors, 2-9 Gigabit LAN ports and multiple DIO ports, and etc.

● Reliable product quality to meet the requirement for 7*24 non-stop operation.Application Area

● Container terminal.Warehousing -

Gantry Crane/Reach Stacker Solution

Gantry Crane/Reach Stacker SolutionBackground

For different applications such as quay cranes, yard cranes, reach stackers and forklift trucks, LYKONDA Technology has designed large-sized in-vehicle computers, and provided various mounting brackets to fasten the computers onto the cabs of different crane sizes. LYKONDA also provides various antenna options (rod, ceiling-mount or FRP), wide-voltage water-proof power supply and waterproof plug-in keyboard. All these have effectively met the customer’s requirement for stability and convenience of use.

Requirements for the Solution

● Medium/Large-size all-in-one in-vehicle computer with touchable display.

● High-gain in-vehicle wireless antenna.

● Mounting bracket.

● Wide-voltage water-proof power supply.

SolutionLYKONDA in-vehicle computers (VT family) provide 7-inch to 12.1-inch touch screens, and runs on Windows operating systems. They contain built-in WiFi, 4G LTE communication modules and GPS positioning module, to facilitate friendly human-machine operation of TOS system, and real-time transmission of dispatch orders.

Solution Advantages

● Reliable product quality to meet the requirement for 7*24 non-stop operation.

● Vehicle standard wide-voltage power input, to support various terminal truck models.

● Multiple screen size (7-12.1-inch) to choose from.

● Full Al-alloy enclosure, fanless design, to meet anti-dust, water-proof and anti-salt-fog standards for the terminal environment.

● Multiple mounting methods, which support various terminal truck models, and render reasonable and effective use of space.Warehousing -

Background Introduction

Background IntroductionFor the management of container trucks at terminals, LYKONDA Technology has designed in-vehicle computers (VT family) and in-vehicle LED displays (VLD family) on various platforms based on the terminal TOS system. LYKONDA also provides various mounting brackets to fix the in-vehicle computers in the narrow cab, and a variety of antenna options (rod, ceiling-mount or FRP), wide-voltage waterproof power supply and waterproof external keyboard. All these have effectively met the customer’s requirements for stability and convenience of use.

Requirements for the Solution

● Medium/Small-size all-in-one in-vehicle computer with touchable display.

● In-vehicle LED display.

● Mounting bracket.

● Wide-voltage water-proof power supply.Solution

LYKONDA Vehicle Mount Computer (VT family) provide 7-inch to 10.4-inch touch screens, and runs on Windows/Android operating systems. They contain built-in WiFi, 4G LTE communication modules and GPS positioning module, to facilitate friendly human-machine operation of TOS system, and real-time transmission of dispatch orders.

The in-vehicle LED displays (VLD family) are mounted in front of the windshield of the container trailer cab. VLDs receive information from in-vehicle computers by serial ports, and display it to the working staff outside the trailer, informing them the type of container lock, destination of the trailer, and etc. In this way, the working efficiency of the terminal can be improved. Furthermore, the LYKONDA TMT family products integrate the LED display and in-vehicle computer, with the LED screen facing outside, and a screen and function keys facing the driver. This all-in-one design makes it easier for customers to install and disassemble the product.Solution Advantages

● Reliable product quality to meet the requirement for 7*24 non-stop operation.

● Vehicle standard wide-voltage power input, to support various terminal truck models.

● Multiple screen size (7-10.4-inch), optional Windows and Android platforms.

● Full Al-alloy enclosure, fanless design, to meet anti-dust, water-proof and anti-salt-fog standards for the terminal environment.

● Multiple mounting methods, which support various terminal truck models, and render reasonable and effective use of space.Application Area

● Container terminal yard.Warehousing -

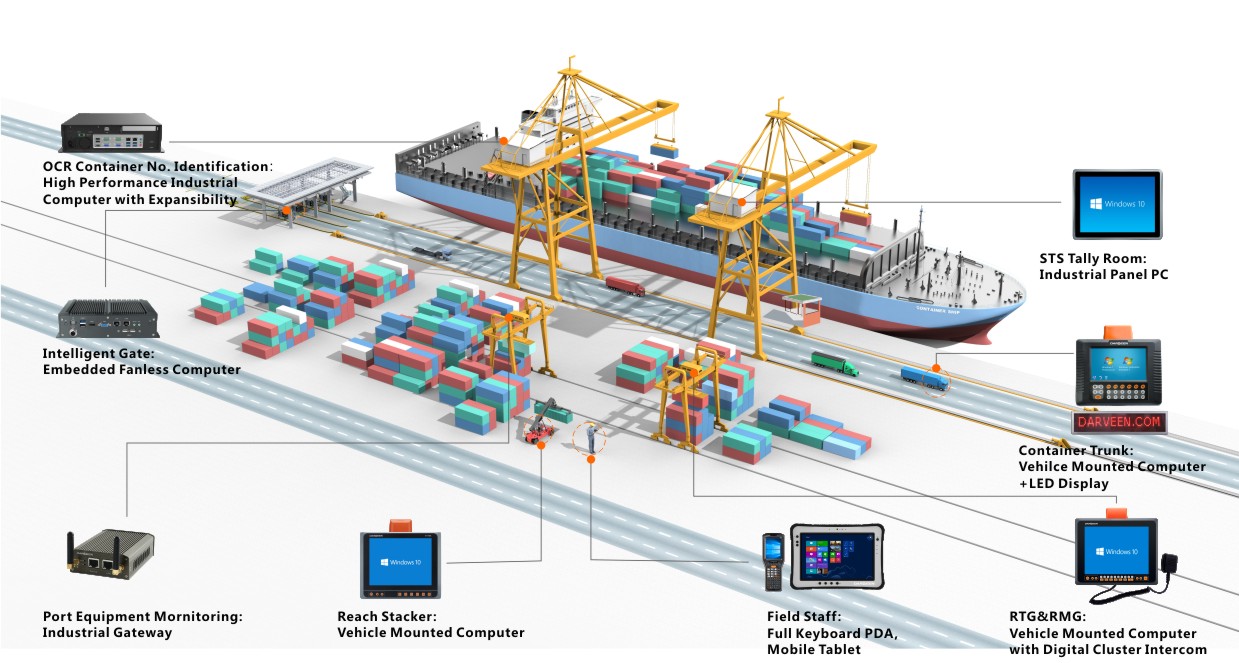

Intelligent Container Port

Intelligent Container PortIn order to meet the different needs of various industries’ fleets for vehicle mount computers, Darveen R&D team hasdeveloped many distinctive features for various applications, including more precise positioning solutions,support for CAN/OBD communication ports to acquire operating status of the vehicles, wide voltage power supply which is adaptable todifferent environments, and more wireless communication methods. After years of development, Darveen has developed aseries of products deeply adored by the users around the world.

Application Area

● Container Truck Solution

● Gantry Crane/Reach Stacker Solution

● Digital Trunking & Data Comm.

● Gate Control Solution

● OCR SolutionWarehousing -

Panel PC for Tyre Building Machine Project Background

Panel PC for Tyre Building Machine Project BackgroundProject Background

China is a big producer and exporter of tires. In the process of tire production, the building process is the key. The semi-finished parts are to be assembled into green tires on the building machine according to the technical specifications. This process is very complex, thus having high requirement for equipment processing and positioning accuracy. Major tire building machine manufacturers have spared no effort to research and develop efficient, accurate, simple-to-use products. The tire equipment manufacturers in China have also made unremitting efforts to develop machines that can meet production requirements in terms of processing, technology and efficiency. With reliable performance and resistance to harsh industrial environment, LYKONDA DPC family industrial panel PCs can bring users a highly efficient, easy-to-install and cost-effective experience.Requirements for the Solution

● Limited space of control cabinet requires space-conscious method for mounting.

● Harsh environment requires higher protection grade.

● High-performance platform to support stable and reliable non-stop operation.Solution Introduction

With compact structure and reliable performance, LYKONDA DPC family industrial panel PCs serve as the upper computers to run the customer operating software and store data. Supporting panel mounting and VESA mounting, the products can seamlessly merge into the control cabinet and save a lot of space. Downwards, the products can connect camera, PLC and other meters and instruments, and provide reliable transmission. With resistance to a variety of complex harsh industrial environments, LYKONDA products provide strong guarantee for customers to improve productivity and product quality.LYKONDA Solution Advantages

● LYKONDA DPC Industrial panel PCs adopt Intel Skylake platform, which features excellent performance with low power consumption.

● All-in-one design, multiple mounting methods, installation space saved and overall appearance improved.

● Highly compatible with various types of old equipment.

● High protection grade, resistance to harsh environments such as dust and irritant gases.Industrial Applications

● Intelligent factories.

● Intelligent logistics.

● Equipment automationWarehousing -

MES Workstation Solution

MES Workstation SolutionProject Introduction

Located in the middle layer of the whole factory system, MES is responsible for integrating all the systems of the factory to form a data platform, including upper layer ERP, underlying connection PLC, data acquisition and display devices. MES automatically receives ERP business order, arranges production and gives production instructions to operators or low layer equipment. Targeting MES applications, LYKONDA Technology has designed a series of industrial panel PCs and MES workstation equipment.Requirements for the Solution

● Unfixed workplace on site, complicated location, harsh installation conditions.

● Numerous types of information acquisition devices require multiple IO ports.

● 24-hour production in factories requires non-stop operation capability.Solution Introduction

LYKONDA DPC family industrial panel PCs can carry out optimal management for the whole production process, from order placement to finished products. With the LYKONDA products, when an incident occurs, users can respond and report in a timely manner, give directions and handle the situation based on current accurate data. LYKONDA products can help reduce activities that have no added value for the enterprise, and effectively guide the production and operation process of the factory. This improves not only the timely delivery capacity and the material flow of the factory, but also the rate of return on production.LYKONDA Solution Advantages

● High quality and reliability of LYKONDA products, to meet customers’ requirement for 7*24 non-stop operation.

● Multiple I/O ports, which enable customers to conveniently connect equipment of various brands and protocols.

● Cost-effective solution to lower the product cost for customers.

● Multiple mounting methods, to support various industrial applications and enable reasonable use of space.

● Various mounting brackets, keyboard tray, scanner bracket, warning light and other accessories to facilitate mounting and use.Warehousing -

ESOP Workstation Solution

ESOP Workstation SolutionProject Background

E-SOP is a management information platform to deliver electronic operating instructions, and realize unified management and centralized control. LYKONDA ESOP terminal controller is a small form factor, fully-functioned and cost-effective industrial computer; Its upper layer is connected to MES system via network, and the lower layer is connected to a monitor to display operating instructions; LYKONDA ESOP control terminal features stability and durability, so it is applicable to 7X24 non-stop operation in factory.Requirements for the Solution

● Unfixed workplace on site, complicated location, harsh installation conditions.

● 24-hour production in factories requires non-stop operation capability.

● Both wired and wireless communication capability.Solution Introduction

The LYKONDA solution includes:

1:Embedded industrial computer + industrial display unit.

● Embedded fanless industrial computer EBC-1122.

● 10.4″~19″ multiple-size industrial display units.

● One-dimensional/two-dimensional scanner.2:All-in-one industrial panel PC.

● DPC family industrial panel PC.

● One-dimensional/two-dimensional scanner.LYKONDA Solution Advantages

● High quality and reliability of LYKONDA products, to meet customers’ requirement for 7*24 non-stop operation.

● Small form factor, compact structure, which is suitable for installation in space-conscious application scenarios.

● Supports both wired and wireless network connection, seamless access to the factory information system.

● Multiple sizes to choose from, to meet various display requirements.Applications

● Intelligent factories.

● Intelligent logistics.Warehousing -

Panel PC for Food Processing

Panel PC for Food ProcessingProject Background

During the food processing and production, a large number of residues and grease will splash onto the equipment, so the equipment needs to be cleaned and flushed from time to time. Over a long period of time, ordinary PCs will wear out and get rusty, which may affect the equipment safety and delay the production.Requirements for the Solution

● Fast and stable computing platform.

● Water-proof design; IO ports meet IP65 protection grade.

● Excellent corrosion resistance of enclosure.Solution Introduction

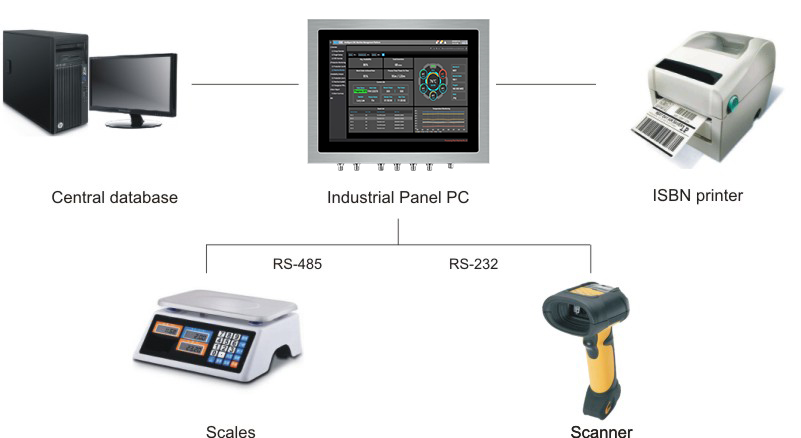

LYKONDA DPC family industrial panel PCs are connected to the central database by Ethernet network, as well as scanner, weighing apparatus and other devices on the lower layers by serial ports. Users can use scanners to acquire place of origin of raw materials and other information, at the same time send product name, production start time, completion time, packaging staff code and other information to the DPC computers for processing. The DPC computers in turn transmit the information to the jet printer, which sprays the generated two-dimensional code onto the package. In this way, consumers can scan the two-dimensional codes to know the production and circulation processes of the food.

LYKONDA Solution Advantages● Reliable product quality to meet customers’ requirement for long-time operation.

● Food-grade stainless steel enclosure, which is rugged, easy to clean and has excellent corrosion resistance.

● M12 water-proof ports provide better protection for internal components, and enable more reliable device connection.

● Specially designed touch screen, which is highly resistant to detergents, disinfectants, and other chemical agents.

● Multiple mounting methods, which support various industrial scenarios, and render reasonable and effective use of space.Application

● Food production and processing.Warehousing -

Forklift Computer for Cold Storage

Forklift Computer for Cold Storage<p>

Background Cold storages are mainly used for storage under constant temperature, ranging from -30℃ to +70℃. The equipment used in storages needs to have waterproof, dustproof and condensation-proof performance. For cold storage logistics, forklifts and computers are usually equipped to realize an information tracing system. Each piece (box) of cargo is assigned a unique identification code, an RFID label or a barcode. So the logistics flow can be tracked and monitored from each piece entering the storage to exiting, and to the terminal sales points. In this way, logistics information automation (including incoming management, warehousing management and delivery management) for all the cargos in the storage can be realized, which improves the logistic efficiency of the storage and lowers the cost. LYKONDA industrial computing system integrates RFID reader and barcode system assembly onto the forklift, and connects them to the internal information system of the company by wireless communication method. LYKONDA solution greatly shortens the time for forklift operators to find the cargo for delivery and transportation, and at the same time sorts out the cargo reasonably, so as to achieve the goals of improved efficiency, cut cost and effective control. LYKONDA in-vehicle computers also have heating function, which has perfectly solved the misting and condensing problems encountered by common electronic devices in the cold storage.

</p>

<p>

Requirements for the Solution<br/>● All-in-one computers with touchable display.<br/>● The computers can run in -30℃ low temperature environment, and the screen has mist elimination function.<br/>● Mounting brackets supporting various forklift models.<br/>● Supports forklifts with various battery capacities, such as 12V, 24V, 48V, 80V, and etc.<br/>● Connect scanners and RFID reader via I/O ports, and they need power supply.

</p>

<p>

Solution<br/>The solution provided by LYKONDA includes:<br/>● LYKONDA in-vehicle computers with heating function.<br/>● Rugged and excellent-performance long distance scanner and scanner bracket.<br/>● Forklift mounting bracket.<br/>● Regulated power supply for forklifts.<br/>● Onsite equipment testing and installation service

</p>

<p>

<br/>

</p>

<p>

Solution Advantages<br/>● Dual-core/Quad-core low power high-performance processors, full Al-alloy fanless rugged in-vehicle computers.<br/>● Screen with PTC heating function, combined with optical bonding technology, can realize defrosting/demisting function.<br/>● U.S military MIL-STD-810G anti-vibration/shock standard, IP66 dustproof and waterproof performance.<br/>● Multiple I/O ports, supporting various high-performance industrial grade scanners.<br/>● Solution equipped with in-vehicle power supply, mounting brackets and industrial water-proof keyboard for multiple forklift models.

</p>

<p>

Application Area<br/>● Forklifts of warehouses

</p>

<p>

</p>

Warehousing -

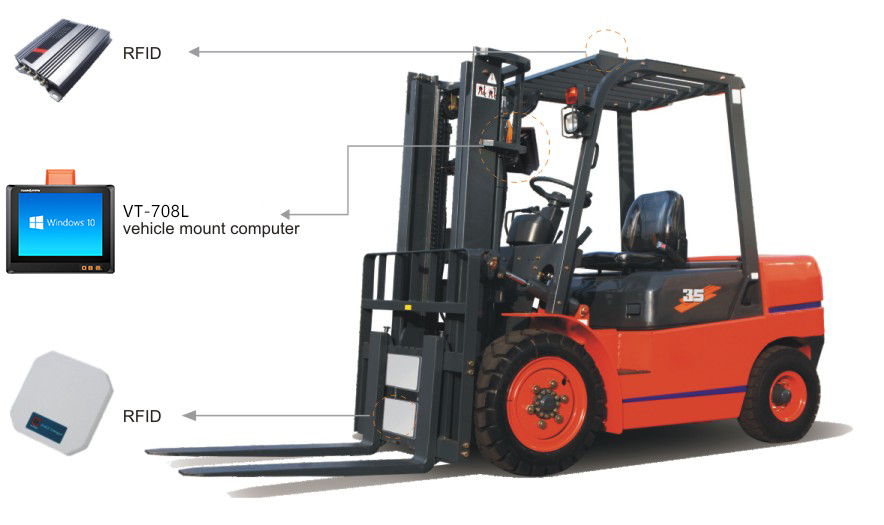

Forklift Computer with RFID Reader

Forklift Computer with RFID ReaderBackground In warehouse management, installing computers, RFID antenna and reader on forklifts can greatly improve the management efficiency and automation level. Installed on the front fork, the RFID antenna can automatically scan the RFID tag of the goods. The received information is transmitted to the RFID reader through cable, and then the reader sends it to the computer by wired or wireless method, thus completing the automatic identification of the goods. Then users can set up WiFi, Narrow Band or directly use 4G mobile phone network as a wireless communication network for the warehouse, and send the data back to the backend server. The whole process cuts the manual service and greatly improves the work efficiency.

Requirements for the Solution

● All-in-one in-vehicle computers with touchable display.

● Mounting brackets that are suitable for various forklift models.

● Supports forklifts with various battery capacities, such as 12V, 24V, 48V, 80V, and etc.

● Connect RFID reader via I/O ports, and scanners need power supply.

● Or built-in Bluetooth module, to communicate with wireless RFID reader.Solution

The solution provided by LYKONDA includes

● Rugged and durable Q10 in-vehicle computer.

● Rugged and excellent-performance industrial grade RFID reader (wired/wireless)

● RFID antenna.

● Onsite testing and installation service.Solution Advantages

● Dual-core/Quad-core low-power high-performance processor, full Al-alloy fanless rugged in-vehicle computer.

● U.S. military MIL-STD-810G anti-vibration/shock standards, IP68 dustproof and waterproof performance.

● Multiple I/O ports, supporting multiple high-performance industrial-grade RFID reader.

● Equipped with in-vehicle power supply, mounting brackets, industrial waterproof keyboard to support multiple forklift models.

● RFID reader can communicate with in-vehicle computers by Bluetooth, instead of cables that need wiring and have wear problem.Warehousing