-

Panel PC for Tyre Building Machine Project Background

Panel PC for Tyre Building Machine Project BackgroundProject Background

China is a big producer and exporter of tires. In the process of tire production, the building process is the key. The semi-finished parts are to be assembled into green tires on the building machine according to the technical specifications. This process is very complex, thus having high requirement for equipment processing and positioning accuracy. Major tire building machine manufacturers have spared no effort to research and develop efficient, accurate, simple-to-use products. The tire equipment manufacturers in China have also made unremitting efforts to develop machines that can meet production requirements in terms of processing, technology and efficiency. With reliable performance and resistance to harsh industrial environment, LYKONDA DPC family industrial panel PCs can bring users a highly efficient, easy-to-install and cost-effective experience.Requirements for the Solution

● Limited space of control cabinet requires space-conscious method for mounting.

● Harsh environment requires higher protection grade.

● High-performance platform to support stable and reliable non-stop operation.Solution Introduction

With compact structure and reliable performance, LYKONDA DPC family industrial panel PCs serve as the upper computers to run the customer operating software and store data. Supporting panel mounting and VESA mounting, the products can seamlessly merge into the control cabinet and save a lot of space. Downwards, the products can connect camera, PLC and other meters and instruments, and provide reliable transmission. With resistance to a variety of complex harsh industrial environments, LYKONDA products provide strong guarantee for customers to improve productivity and product quality.LYKONDA Solution Advantages

● LYKONDA DPC Industrial panel PCs adopt Intel Skylake platform, which features excellent performance with low power consumption.

● All-in-one design, multiple mounting methods, installation space saved and overall appearance improved.

● Highly compatible with various types of old equipment.

● High protection grade, resistance to harsh environments such as dust and irritant gases.Industrial Applications

● Intelligent factories.

● Intelligent logistics.

● Equipment automationWarehousing -

MES Workstation Solution

MES Workstation SolutionProject Introduction

Located in the middle layer of the whole factory system, MES is responsible for integrating all the systems of the factory to form a data platform, including upper layer ERP, underlying connection PLC, data acquisition and display devices. MES automatically receives ERP business order, arranges production and gives production instructions to operators or low layer equipment. Targeting MES applications, LYKONDA Technology has designed a series of industrial panel PCs and MES workstation equipment.Requirements for the Solution

● Unfixed workplace on site, complicated location, harsh installation conditions.

● Numerous types of information acquisition devices require multiple IO ports.

● 24-hour production in factories requires non-stop operation capability.Solution Introduction

LYKONDA DPC family industrial panel PCs can carry out optimal management for the whole production process, from order placement to finished products. With the LYKONDA products, when an incident occurs, users can respond and report in a timely manner, give directions and handle the situation based on current accurate data. LYKONDA products can help reduce activities that have no added value for the enterprise, and effectively guide the production and operation process of the factory. This improves not only the timely delivery capacity and the material flow of the factory, but also the rate of return on production.LYKONDA Solution Advantages

● High quality and reliability of LYKONDA products, to meet customers’ requirement for 7*24 non-stop operation.

● Multiple I/O ports, which enable customers to conveniently connect equipment of various brands and protocols.

● Cost-effective solution to lower the product cost for customers.

● Multiple mounting methods, to support various industrial applications and enable reasonable use of space.

● Various mounting brackets, keyboard tray, scanner bracket, warning light and other accessories to facilitate mounting and use.Warehousing -

ESOP Workstation Solution

ESOP Workstation SolutionProject Background

E-SOP is a management information platform to deliver electronic operating instructions, and realize unified management and centralized control. LYKONDA ESOP terminal controller is a small form factor, fully-functioned and cost-effective industrial computer; Its upper layer is connected to MES system via network, and the lower layer is connected to a monitor to display operating instructions; LYKONDA ESOP control terminal features stability and durability, so it is applicable to 7X24 non-stop operation in factory.Requirements for the Solution

● Unfixed workplace on site, complicated location, harsh installation conditions.

● 24-hour production in factories requires non-stop operation capability.

● Both wired and wireless communication capability.Solution Introduction

The LYKONDA solution includes:

1:Embedded industrial computer + industrial display unit.

● Embedded fanless industrial computer EBC-1122.

● 10.4″~19″ multiple-size industrial display units.

● One-dimensional/two-dimensional scanner.2:All-in-one industrial panel PC.

● DPC family industrial panel PC.

● One-dimensional/two-dimensional scanner.LYKONDA Solution Advantages

● High quality and reliability of LYKONDA products, to meet customers’ requirement for 7*24 non-stop operation.

● Small form factor, compact structure, which is suitable for installation in space-conscious application scenarios.

● Supports both wired and wireless network connection, seamless access to the factory information system.

● Multiple sizes to choose from, to meet various display requirements.Applications

● Intelligent factories.

● Intelligent logistics.Warehousing -

Panel PC for Food Processing

Panel PC for Food ProcessingProject Background

During the food processing and production, a large number of residues and grease will splash onto the equipment, so the equipment needs to be cleaned and flushed from time to time. Over a long period of time, ordinary PCs will wear out and get rusty, which may affect the equipment safety and delay the production.Requirements for the Solution

● Fast and stable computing platform.

● Water-proof design; IO ports meet IP65 protection grade.

● Excellent corrosion resistance of enclosure.Solution Introduction

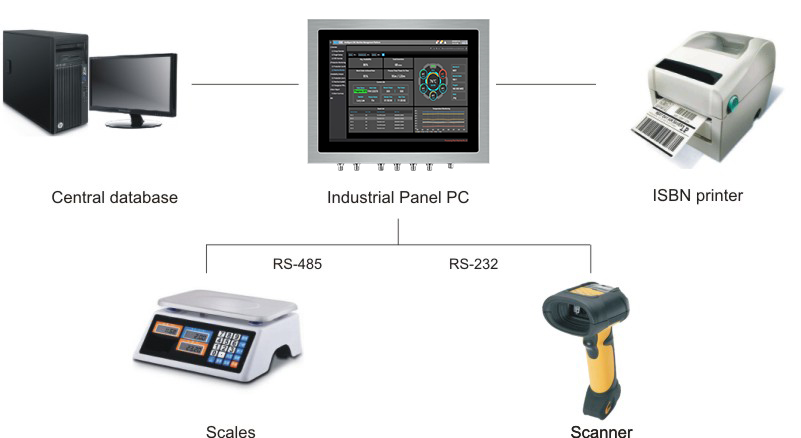

LYKONDA DPC family industrial panel PCs are connected to the central database by Ethernet network, as well as scanner, weighing apparatus and other devices on the lower layers by serial ports. Users can use scanners to acquire place of origin of raw materials and other information, at the same time send product name, production start time, completion time, packaging staff code and other information to the DPC computers for processing. The DPC computers in turn transmit the information to the jet printer, which sprays the generated two-dimensional code onto the package. In this way, consumers can scan the two-dimensional codes to know the production and circulation processes of the food.

LYKONDA Solution Advantages● Reliable product quality to meet customers’ requirement for long-time operation.

● Food-grade stainless steel enclosure, which is rugged, easy to clean and has excellent corrosion resistance.

● M12 water-proof ports provide better protection for internal components, and enable more reliable device connection.

● Specially designed touch screen, which is highly resistant to detergents, disinfectants, and other chemical agents.

● Multiple mounting methods, which support various industrial scenarios, and render reasonable and effective use of space.Application

● Food production and processing.Warehousing -

The Application of LYKONDA RFID Reader EV10 in Logistics Management

The Application of LYKONDA RFID Reader EV10 in Logistics ManagementDemands: The acceleration of economic globalization and the significant importance of modern logistics to economic development indicates that in the future, the market competition is actually the competition of enterprise supply chain. The key to supply chain and logistics management depends on the accuracy and timeliness in information transmitting. Challenges: Traditional management methods are mostly implemented by manual registration or scanning QR barcode, which can not guarantee the extreme information collection speed and the immense accuracy, fail to meet demand to collect and record the massive amount of information in modern logistics. Traditional logistics management could lead more wast in time and labor cost, which may increase the logistics cost and reduce the core competitiveness of logistics companies. LYKONDA solutions: LYKONDA RFID reader EV10 based on RFID technology, combining with warehouse management software, integrates various types of intelligent mobile terminals of LYKONDA devices to solute real time warehouse management automatically such as receiving, warehousing, picking, assembling, stock-taking, outbound, assembling, positioning, scheduling and other logistic activities. LYKONDA RFID reader EV10 can greatly improve the degree of automation, greatly reduce errors to realize modern logistics management in such targets as efficient, scientific and low-cost. Effects: Without opening the outer packaging of the product, LYKONDA EV10 can identify the chip ID cards in the boxes and packages, so that the relevant information of the product can be obtained accurately at any time, which can not only greatly improve the degree of automation, but also greatly reduce the error rate. By group scanning and group reading, the inventory task is initiated through LYKONDA EV10 and handheld devices to generate grouped inventory list. In positioning management, truck and pallets label are uploaded in real time through RFID reader EV10 to complete the real-time positioning of goods. By collecting and uploading relevant information through LYKONDA EV10 RFID reader, you can query the status, location, cargo information, orders, etc. Of each item in the logistics supply chain. Also, LYKONDA EV10 RFID reader could realize the first-in-first out management of goods. For products with hight time limit requirements, advanced warehouses will give priority to deliver them from warehouse and provide reminders to be out of the warehouse. Forklifts can receive reminder information and accurately find the location for operation. LYKONDA EV10 RFID reader is based on the RFID chip technology, which has the characteristics of ultra-low cost, high security and high reliability, and the data can not be physically erased. Digital data storage in RFID technology can last more than 100 years, anti-fouling, anti-irradiation, high and low temperature resistance, anti-harsh environment. LYKONDA EV10 based on RFID technology can work in long-distance, no-visual recognition, 100% recognition rate, realize rapid identification of material batches and intelligent inventory. Big data analysis can early remind warning of inventory and out-of-stock conditions. Automatic statistical data in all aspects of warehousing improves work efficiency to provide decision support through real-time analysis and to improve warehouse throughput. Configuration: EV10 Functions: RFID reading and writing, Bluetooth, GPS, Wi-Fi.

Warehousing

- 共1页 5条